Opis produktu:

Stopy stalowe Metal jest powszechnie uznawany za wyjątkową wytrzymałość, trwałość i wszechstronność, co czyni go niezbędnym materiałem w różnych zastosowaniach przemysłowych.Wśród różnych rodzajów stali stopowej dostępnych na rynku, Inconel 600 Alloy Steel Plate wyróżnia się jako produkt premium, oferujący wyjątkową wydajność i niezawodność.Produkt ten łączy w sobie unikalne właściwości stali stopowej z zaawansowanymi technikami produkcji, w wyniku czego powstaje materiał spełniający najwyższe standardy jakości i funkcjonalności.

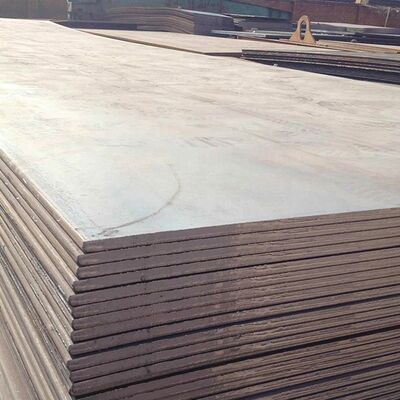

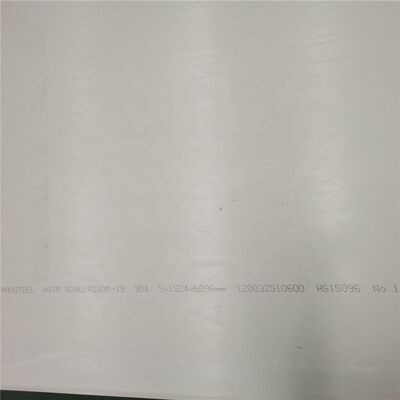

Jedną z charakterystycznych cech płyt stalowych stopu Inconel 600 jest ich wykończenie powierzchni.każdy spełniający określone wymagania estetyczne i funkcjonalneJasna powierzchnia zapewnia gładki, odbijający wykończenie, które jest idealne dla zastosowań, w których wygląd i odporność na korozję są kluczowe.wykończenie nieodbijające, które jest odpowiednie do środowisk przemysłowych, w których konieczne jest zmniejszenie oślepień i dodatkowa ochrona powierzchniObie opcje powierzchni podkreślają wszechstronność i adaptacyjność tego metalowego produktu ze stali stopowej.

Proces produkcji tych płyt metalowych ze stali stopowej obejmuje skrupulatną procedurę obróbki cieplnej zwaną ugaszaniem i hartowaniem.Ta obróbka cieplna znacząco zwiększa właściwości mechaniczne materiału, w tym jego twardość, wytrzymałość i odporność na zużycie i zmęczenie.podczas gdy temperując następuje zmniejszenie kruchości i poprawa elastycznościPołączenie to zapewnia, że blachy Inconel 600 ze stali stopowej zachowują optymalną wydajność nawet w ekstremalnych warunkach,co sprawia, że są one idealne do stosowania w wymagających zastosowaniach przemysłowych, takich jak lotnictwo kosmiczne, wytwarzania energii i przetwarzania chemicznego.

Innym kluczowym atrybutem tego metalu ze stali stopowej jest jej temperatura topnienia, która waha się od 1425 do 1540 °C.Dzięki wysokiej temperaturze topnienia materiał jest odporny na podwyższone temperatury, nie naruszając jego struktury ani właściwości mechanicznychTaka stabilność termiczna ma kluczowe znaczenie w zastosowaniach, w których elementy są narażone na intensywne ciepło, na przykład w silnikach turbinowych, wymiennikach ciepła i częściach pieca. The ability of the Inconel 600 Alloy Steel Plate Sheets to retain strength and resist oxidation at high temperatures sets it apart from many other materials and reinforces its reputation as a reliable alloyed metal steel product.

Rodzaj materiału jest podstawowym elementem przy wyborze stali do dowolnego zastosowania, a płyty Inconel 600 Alloy Steel Plate są wykonane z stali stopowej klasy premium.Metali stopowe ze stali cechują się dodaniem różnych pierwiastków stopowych, takich jak chromW związku z powyższym należy zwrócić uwagę na fakt, że w odniesieniu do stali nierdzewnej istnieją różne rodzaje stali, takie jak:powodując materiał, który działa wyjątkowo dobrze w trudnych warunkachWykorzystanie stali stopowej zapewnia, że produkt spełnia rygorystyczne normy przemysłowe i spełnia specyficzne potrzeby sektorów wymagających materiałów o wysokich osiągach.

Podsumowując, blachy ze stali stopowej Inconel 600 stanowią wyższą kategorię metalu stopowego, zaprojektowaną w celu zapewnienia doskonałej wydajności w szerokim zakresie zastosowań.Z opcjami powierzchni w zakresie od jasnych do czarnych wykończeń, zaawansowana obróbka cieplna przez ugotowanie i hartowanie, wysoka temperatura topnienia w zakresie od 1425 do 1540 °C oraz wrodzone zalety stali stopowej jako rodzaju materiału,produkt ten idealnie nadaje się do przemysłu wymagającego wytrzymałości, trwałości i stabilności termicznej.te płyty ze stali stopowej stanowią niezawodne i wydajne rozwiązanie, które spełnia i przekracza oczekiwania.

Parametry techniczne:

| Odporność na korozję |

Średnia do wysoka |

| Klasa |

Inconel 600, 601, 625, 800, 800HT, 800H, 901, 925, 926, 718 |

| Punkt topnienia |

1425 - 1540 °C |

| Zawartość węgla |

00,05% - 2,0% |

| Rodzaj materiału |

Stali stopowych |

| Obsługa cieplna |

Zgaszenie i rozgrzewanie |

| Specyfikacja |

SGS BV |

| Siła wydajności |

350 - 1000 MPa |

| Wytrzymałość na rozciąganie |

600 - 1200 MPa |

| Powierzchnia |

Jasny, czarny. |

Zastosowanie:

Stali stopu metalu, znany ze swojej wyższej wytrzymałości i trwałości, znajduje szerokie zastosowanie w szerokim zakresie branż i scenariuszy.Ta stal ze stopu metalowego oferuje wyjątkową wytrzymałość na rozciąganie między 600 a 1200 MPaPowierzchnia tej stali stopowej dostępna jest w jasnych i czarnych barwach,zapewnienie zarówno atrakcyjności estetycznej, jak i odporności na korozję w zależności od specyficznych wymagań projektu.

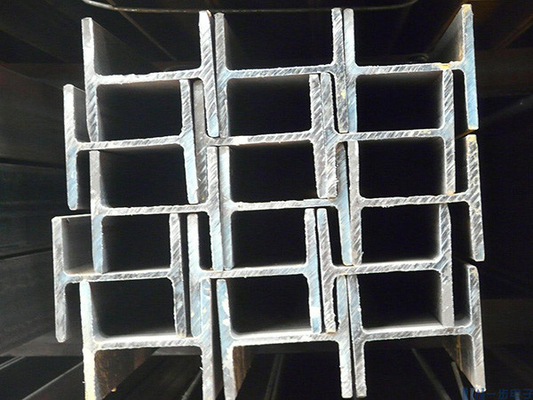

Jednym z najczęstszych zastosowań metalu stopu stalowego jest w przemyśle budowlanym.jest szeroko stosowany w produkcji ramW projektach architektonicznych, w których atrakcyjność wizualna jest ważna, często preferowane są jasne wykończenia powierzchni.natomiast czarne wykończenie powierzchni jest wybierane do zastosowań przemysłowych i zewnętrznych, w których konieczna jest dodatkowa ochrona przed czynnikami środowiskowymi.

W sektorze motoryzacyjnym i transportowym stal stopowa ma kluczowe znaczenie dla produkcji części wymagających równowagi siły i elastyczności, takich jak elementy podwozia, przekładnie,i części silnikówDokładna kontrola zawartości węgla zapewnia, że stop może wytrzymać wysokie naprężenia i uderzenia, zwiększając bezpieczeństwo i wydajność pojazdów.jego opakowanie w opakowaniach z materiałem wodoodpornym zapewnia, że Metal Stopy Stalowej zachowuje swoją integralność i jakość podczas transportu i przechowywania, zapobiegając rdzewi i uszkodzeniom.

Stal stopowa jest również szeroko stosowana w produkcji maszyn ciężkich i sprzętu przemysłowego.Jego wysoka wytrzymałość na rozciąganie i certyfikowane standardy jakości sprawiają, że nadaje się do produkcji trwałych części maszynowych, narzędzi i sprzętu, które działają w warunkach wysokiego ciśnienia i obciążenia.Dostępność różnych wykończeń powierzchniowych pozwala producentom wybrać najlepszą opcję dla ich konkretnego środowiska i potrzeb operacyjnych.

Ponadto metale ze stopu stali mają ważne zastosowania w sektorach energetycznych, takich jak ropa naftowa i gaz, gdzie są stosowane w rurociągach, sprzęcie wiertniczym i zbiornikach magazynowych.Połączenie wysokiej wytrzymałości, odporność na korozję i certyfikowana jakość zapewniają długowieczność i bezpieczeństwo w tych kluczowych zastosowaniach.Stal stopowa wyróżnia się jako niezawodny i wszechstronny materiał, poparte doskonałymi właściwościami mechanicznymi i opakowaniami ochronnymi.

Dostosowanie:

Nasze produkty ze stali stopowej dostępne są z kompleksowymi usługami dostosowywania produktów, aby spełnić Państwa wymagania.te elementy ze stali stopowej poddawane są precyzyjnym procesom obróbki cieplnej, takim jak tłumienie i hartowanie, aby zwiększyć wytrzymałość i trwałośćNasz stopiony stal zapewnia doskonałą wydajność w ekstremalnych warunkach.

Oferujemy różne wykończenia powierzchni, w tym jasne i czarne opcje, aby spełnić różne potrzeby estetyczne i funkcjonalne.certyfikowane przez BV i SGS, gwarantujące niezawodność i jakość.Nasze usługi dostosowywania metalu stopu stalowego dostarczają doskonałych rozwiązań dla Twoich aplikacji.

Opakowanie i wysyłka:

Nasze produkty ze stali stopowej są starannie pakowane, aby zapewnić maksymalną ochronę podczas transportu.korozjaW celu zwiększenia bezpieczeństwa produkty umieszczane są w solidnych drewnianych skrzyniach lub wzmocnionych stalowych pojemnikach, w zależności od wielkości i ilości.

Używamy materiałów amortyzujących, takich jak foam padding lub foam wrap, aby zminimalizować ruch w opakowaniu.Wszystkie opakowania są wyraźnie oznakowane instrukcjami obsługi i szczegółami produktu w celu ułatwienia płynnego przetwarzania podczas wysyłki.

Wysyłka jest obsługiwana przez wiarygodnych przewoźników z doświadczeniem w obsłudze ciężkich i przemysłowych materiałów.usługi przyspieszoneInformacje dotyczące śledzenia są dostarczane klientom w celu monitorowania stanu przesyłki w czasie rzeczywistym.

Nasze zobowiązanie do wysokiej jakości opakowań i efektywnej wysyłki zapewnia, że produkty ze stali stopowej docierają do miejsca przeznaczenia w optymalnym stanie, gotowe do natychmiastowego użytku.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!